The 15mm Stalingrad project been progressing over the normal discovery course that all my convention game projects seem to follow. You know, a brief Eureka! moment, followed by frenzied research about the event, an expansion of the original concept because "it's got to be big!" which is quickly followed by a shattering dread that the project is impossible to pull off.

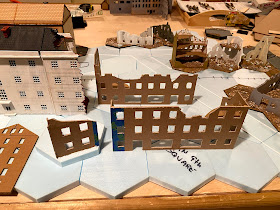

That last stage occurred a little over a week ago - right after I finished the final map mock-up of central Stalingrad and counted the number of buildings/ruins that need to be made. Rather than post specific numbers, which may induce you to call the authorities and have me put away in a asylum, lets just stick with the elegant and descriptive term "metric but ton" or MBT for short.

In despair, I was casting about the internet with thoughtful search terms like "holy crap, I'm a moron" and "Wargame terrain Magic Wands" when I stumbled across a model railroad channel where they used a Cricut Cutter to make building for the layout. Normally, any self respecting miniature gamer would eschew the dingy world of Model railroading but these are desperate times. The device pictured above is called a Cricut Mamer and retails for $300 (US). It's a computer controlled cutter that cuts across and x and y axis. The beauty of the device is the controlling software which allows you to drop any image in and have the damn thing cut it out - including super complex designed. It's not a laser cutter sot the depth of the materials is limited - but for 15mm building walls 2mm thick bass wood and chipboard are perfect.

I use a free program called inkscape to create building designs - it's really easy, upload them the the Cricut design space and let it cut away. Unlike a 3D printer, I've have yet to to have a misprint that was not the fault of my design - no spaghetti monsters, no slip prints etc. I've also learned to test cut on regular printer paper before using thicker materials.

Hey that is great!

ReplyDeleteI have used our Silhouette Cameo a bunch of times for modeling stuff, but it is an early model, and can not cut chipboard or styrene. It is certainly adequate for stencils and paper details, which when you super glue are nearly as hard as plastic (if more fiddly to use).

And having just started on the 3d printer malarkey, I am not sure which one is easier yet... they are both pretty frustrating! Quick design making is easy, execution is hard (and might rely on quality designs).

I been 3d printing over a year and half. Yes I have some failures. But one has to keep on top of the machine. Basically checking for loose components. Making sure the jack screw is lightly oiled. But the key is in the slicer program. I have posted some videos on this on my Blog. Just finished a Stalingrad Department store in 20 mm for a customer. Also with cobblestone streets. I have a Cameo and knew about styrene be not MDF. Do have a link to the rail sight that explains how to use the cameo? Thanks. Current I'm printing the same Department store in 15mm

ReplyDelete